COOLCO’S FOUR KEY SUSTAINABILITY FOCUS AREAS

Environment

Social

Governance

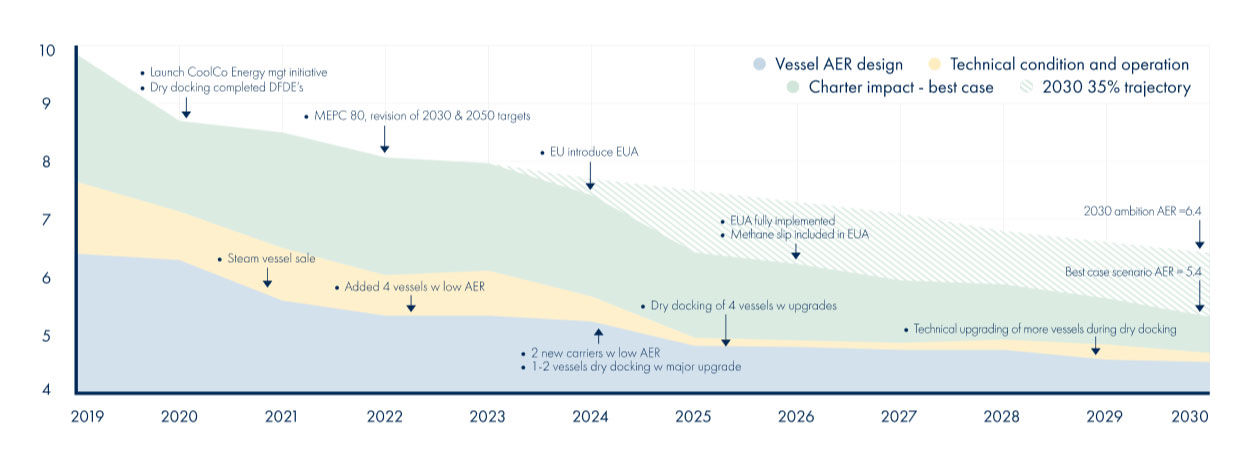

DECARBONIZATION STRATEGY

We have developed a decarbonization strategy centered on specific aspects of vessel performance within our control. These areas include:

Optimize vessel condition

Vessel Condition: In our effort to enhance environmental sustainability and optimize operational efficiency, we are committed to maintaining the highest standard of vessel condition. This encompasses, for example, regular inspections and maintenance routines for our engines, hull, and propellers, ensuring they remain in optimal working condition at all times.

Minimize Onboard Energy Consumption: We are dedicated to minimizing onboard energy consumption through various strategies. This includes optimizing the number of engines running at any given time and managing hotel load efficiently. By minimizing energy usage, we aim to reduce our environmental impact and promote responsible resource management within our operations.

Collaboration with charterers

CoolCo actively collaborates with charterers to optimize vessel routes, speeds, and fuel consumption. We aim to reduce emissions by encouraging the use of the safest and most energy-efficient routes.

Since 2022, CoolCo launched several collaborative pilot projects in partnership with some of our key charterers. These initiatives allowed us to explore innovative strategies and technologies to further enhance the safety, efficiency, and eco-friendliness of our operations, reinforcing our dedication to sustainable maritime practices.

Technical upgrade of vessel

Upgrading vessels to enhance energy efficiency and invest in CO2 and methane emissions abatement technologies.

As vessels become due for dry-docking, upgrading them with cargo reliquefaction and hull air lubrications systems to greatly improve environmental performance.

Next Generation LNG Carrier design

We are exploring future designs for next generation low-emission LNG Carriers with the goal of rendering them compliant with the IMO 2050 net-zero targets.

The designs are prepared for an array of upgrades and solutions that we expect to become available in the coming years.

LNG-E BY COOLCO

LNG-E by CoolCo represents a cutting-edge approach to liquefied natural gas carriers. Our LNG-E vessels boast advanced features including state-of-the-art sub-coolers, air lubrication systems, and a variety of other optimizations that collectively make a substantial impact. These enhancements include dynamic boil-off gas (BOG), trim optimization, real-time data feedback to our dedicated performance team, additional meters for precise monitoring, hull coating and robot cleaning technologies, boss cap fins, and improved diesel generator performance.

One notable feature is the incorporation of the latest sub-cooler technology (as of October 2023), capable of reliquefying surplus BOG at a rate of 2.1 MT/hr. This innovative system ensures efficient reliquefaction, particularly when the vessel is ordered by charterers to be stationary and is used for storage.